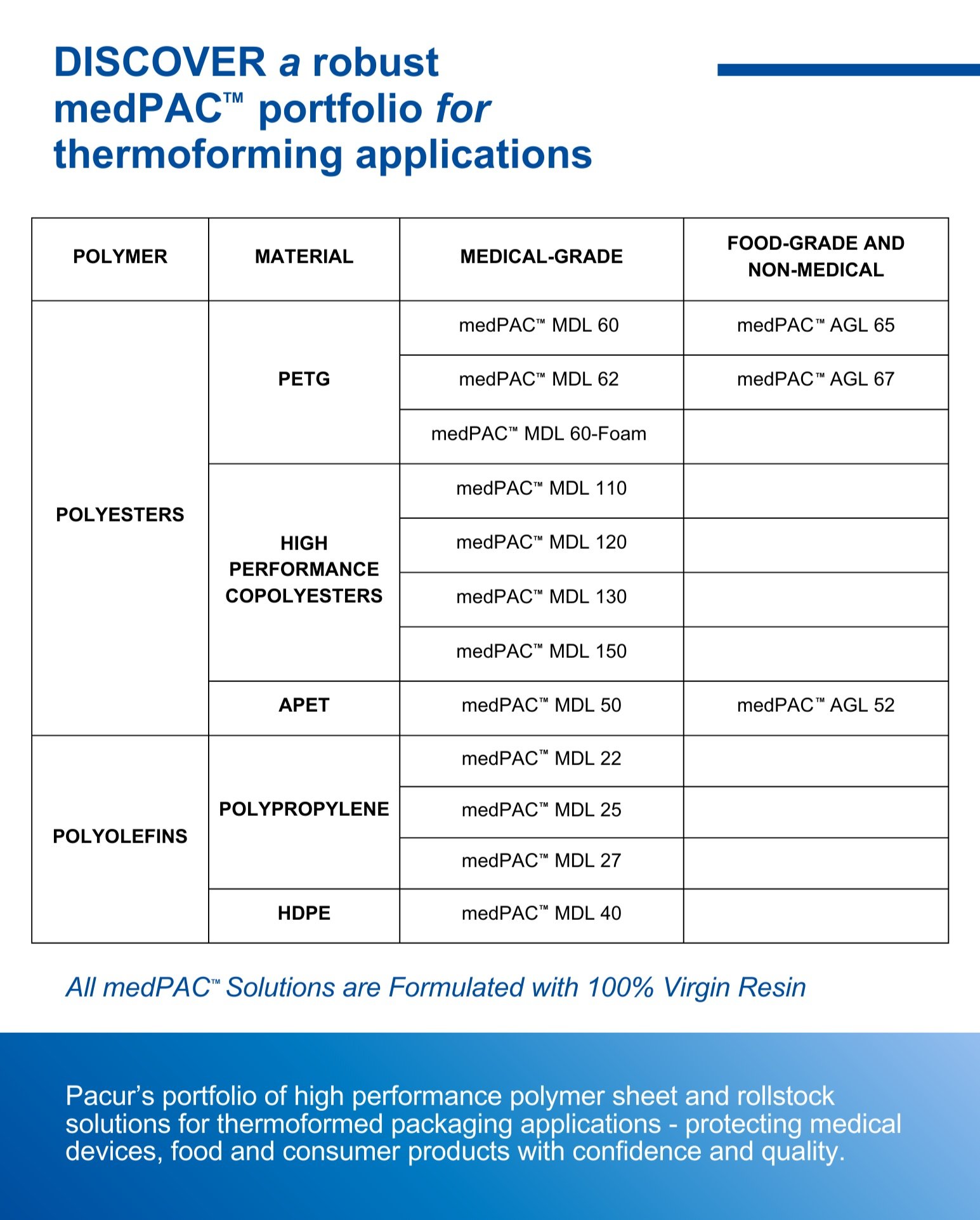

medPAC PETG SOLUTIONS

MDL 60 PETG

MDL 60 is a glycol-modified polyethylene terephthalate (PETG) sheet and rollstock solution extruded from Eastman Eastar 6763 copolyester resin. It is exceptionally clear, remarkably tough, has good impact and puncture resistance proving excellent protection and easy identification of sterile barrier packed contents. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It is easily sealed to a variety of substrates. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO), gamma, electron beam and plasma gas sterilization with excellent post-sterilization optical and physical stability. Providing manufacturers with confidence, MDL 60 is the ideal solution for sterile barrier rigid medical device packaging, pharmaceutical blister packaging, dental devices, food and general consumer blister packaging applications.

MDL 62 PETG

MDL 62 is a glycol-modified polyethylene terephthalate (PETG) sheet and rollstock solution. It is exceptionally clear, remarkably tough, has good impact and puncture resistance proving excellent protection and easy identification of sterile barrier packed contents. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It is easily sealed to a variety of substrates. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO), gamma, electron beam and plasma gas sterilization with excellent post-sterilization optical and physical stability. Providing manufacturers with confidence, MDL 62 is the ideal solution for sterile barrier rigid medical device packaging, pharmaceutical blister packaging, dental devices, food and general consumer blister packaging applications.

AGL 65 PETG

AGL 65 is a utility-grade, virgin glycol-modified polyethylene terephthalate (PETG) sheet and rollstock solution formulated with virgin PETG copolyester resin. AGL 65 is exceptionally clear, remarkably tough, has good impact and puncture resistance proving excellent protection and easy identification of packed contents. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It is easily sealed to a variety of substrates. It meets REACH, RoHS, CONEG and CA Proposition 65 requirements. Providing manufacturers with confidence, AGL 65 is the ideal solution for utility-grade packaging material and specialty thermoforming applications.

AGL 67 PETG

AGL 67 is a utility-grade, virgin glycol-modified polyethylene terephthalate (PETG) sheet and rollstock solution formulated with virgin PETG copolyester resin. AGL 67 is exceptionally clear, remarkably tough, has good impact and puncture resistance proving excellent protection as a acrylic alternative for protective barriers. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It meets REACH, RoHS, CONEG and CA Proposition 65 requirements. Providing manufacturers with confidence, AGL 67 is the ideal solution for utility-grade packaging material and specialty thermoforming applications.

MDL 60-Foam PETG

MDL 60 Foam is a PETG copolyester with a proprietary foamed core. It is a styrene-free alternative to high impact polystyrene (HIPS), where low weight and sustainability are key requirements. It presents significant advantages and improvements over HIPS in terms of yield, processing ease, waste reduction, sustainability and overall lower processing costs. It offers excellent impact, notch and tear resistance. It is easily formed, cut and trimmed with good heat seal performance to common lidding materials. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It is easily sterilized using ethylene oxide (EO), gamma, electron beam and plasma gas. Providing manufacturers with confidence in reliability and sustainability, MDL 60 Foam is the ideal solution for opaque rigid medical packaging as well as die-cut medical cards and inserts.

medPAC HIGH PERFORMANCE COPOLYESTERS

MDL 110 HT

MDL 110, formerly known as ‘PACUR HT’ is a high-performance amorphous copolyester sheet and rollstock solution that delivers higher and lower temperature and chemical resistance than MDL 60, satisfying higher performance requirements for specialty applications and expedited shelf-life validation. MDL 110 is extraordinarily clear and has superior toughness. It has excellent impact properties and puncture resistance. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It is easily sealed to a variety of substrates. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO), gamma, electron beam and plasma gas sterilization with excellent post-sterilization stability. MDL 110 provides superior protection of package contents and retention of the sterile barrier. The high glass transition temperature allows more rapid accelerated-aging protocols for shelf-life qualification and a faster EO cycle time - reducing time and labor and increasing confidence.

MDL 120 HT

MDL 120 is a high-performance amorphous copolyester sheet and rollstock solution that delivers higher temperature and chemical resistance than MDL 60, satisfying higher performance requirements for specialty thermoformed applications, like dental aligners and appliances. MDL 120 is extraordinarily clear and has superior toughness. It has excellent impact properties and puncture resistance. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It is easily sealed to a variety of substrates. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO), gamma, electron beam and plasma gas sterilization with excellent post-sterilization stability. MDL 120 provides superior protection of package contents and retention of the sterile barrier, as well as a slightly higher tensile strength and modulus of elasticity than MDL 110.

MDL 130 HT

MDL 130 is a high-performance amorphous copolyester sheet and rollstock solution that delivers higher temperature and chemical resistance than MDL 60, satisfying higher performance requirements for dental aligners and other specialty applications. MDL 130 is impeccably clear and stain resistant. It is remarkably tough with excellent impact properties and puncture resistance. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It meets ISO 10993 and USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO), gamma and electron beam sterilization.

MDL 150 HT

MDL 150 is a high-performance copolyester sheet and rollstock solution that satisfies high performance requirements for dental aligners and other specialty applications. MDL 150 is clear, tough, stain and wear resistant. It is easy to mold with little to no trim dust, no stress whitening and can be processed within a wide thermoforming window. It meets ISO 10993 and USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. It withstands ethylene oxide (EO) and electron beam sterilization.

medPAC APET SOLUTIONS

MDL 51 APET

MDL 51 is an amorphous polyethylene terephthalate (APET) sheet and rollstock solution extruded from virgin polyester resin. It is an exceptionally clear, medical grade material that offers an excellent oxygen permeability barrier for packaging of oxygen-sensitive products. It meets ISO 10993/USP Class VI biocompatibility, FDA, USDA, REACH and CA Proposition 65 requirements. MDL 51 is highly recyclable with a Resin ID Code #1. It is remarkably tough with great impact and chemical resistance. It is easy to mold with minimal trim dust, no stress whitening and can be processed within a wide thermoforming window. Providing manufacturers with confidence, MDL 51 is a great solution for medical, pharmaceutical, food, cosmetic and general purpose packaging.

AGL 52 APET

AGL 52 is an amorphous polyethylene terephthalate (APET) sheet and rollstock solution extruded from virgin polyester resin. It meets REACH, RoHS and CA Proposition 65 requirements. AGL 52 is highly recyclable with a Resin ID Code #1. It is tough with great impact and chemical resistance. It is easy to mold with minimal trim dust, no stress whitening and can be processed within a wide thermoforming window. Providing manufacturers with confidence, AGL 52 is a great solution for general purpose packaging.

medPAC POLYPROPYLENE SOLUTIONS

MDL 22 Polypropylene

MDL 22, formerly known as Pacur PROP 7020, is a clarified random copolymer, medical grade polypropylene. It boasts excellent processability, clarity, impact resistance and sterile barrier protection. The low stress composition, consistent gauge and anti-static properties achieve high yield processing with fewer rejected parts. Standard sterilization methods include the use of ethylene oxide or autoclave and steam formulations. It has great transparency, impact and puncture resistance providing confident protection and easy identification of sterile barrier packed contents. It is easy to thermoform with little stress. It meets FDA, REACH and CA Proposition 65 requirements. Providing manufacturers with confidence, MDL 22 is a great solution for sterile barrier rigid healthcare packaging, pharmaceutical blister packaging, food, cosmetics and electronic packaging, as well as specialty thermoformed applications.

MDL 25 Polypropylene

MDL 25, formerly known as Pacur PROP 6025, is a high-heat general purpose homopolymer, medical grade polypropylene. It boasts excellent heat and impact resistance. It is a highly crystalline homopolymer that meets USP Class VI biocompatibility, FDA, REACH and CA Proposition 65 requirements. The low stress composition, consistent gauge and physical properties achieve high yield processing with fewer rejected parts. Standard sterilization methods include the use of ethylene oxide or available autoclave steam formulations. Providing manufacturers with confidence, MDL 25 is a great solution for sterile barrier rigid medical device packaging, pharmaceutical blister packaging, food, cosmetics and general purpose packaging, as well as specialty thermoformed applications that require a high-heat polypropylene solution.

MDL 27 Polypropylene

MDL 27, formerly known as Pacur PROP 7000, is a high- impact copolymer, medical grade polypropylene. It meets USP Class VI biocompatibility, FDA, REACH and CA Proposition 65 requirements. The low stress composition, consistent gauge and physical properties achieve high yield processing with fewer rejected parts. Standard sterilization methods include the use of ethylene oxide or available autoclave and steam formulations. Providing manufacturers with confidence, MDL 27 is a great solution for sterile barrier rigid medical device packaging, pharmaceutical blister packaging, food, cosmetics and general purpose packaging, as well as specialty thermoformed applications that require a high-impact polypropylene solution.